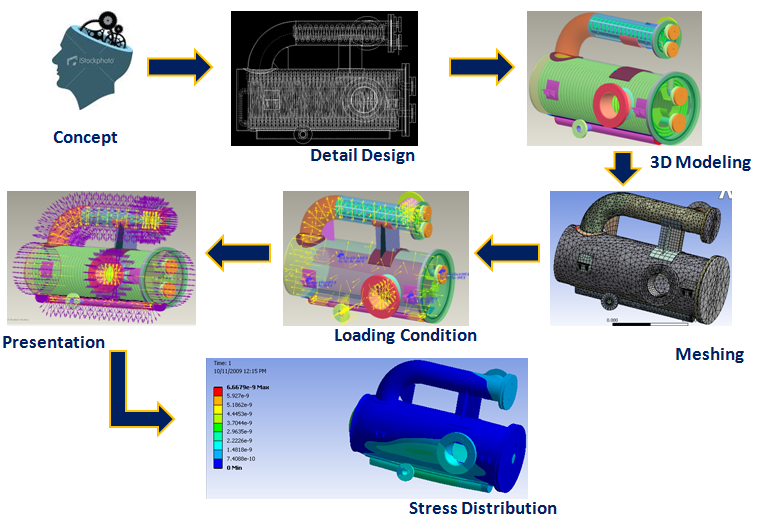

In our approach to design we apply the same principle as we do in everything else – making sure we totally grasp and understand our customers’ requirements, goals and expectations right from the very earliest days in the life of the project.

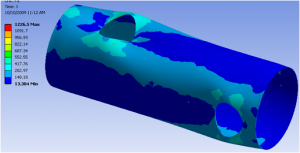

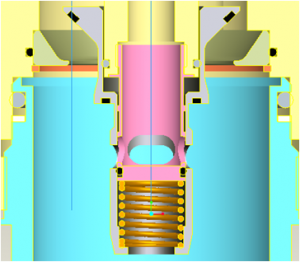

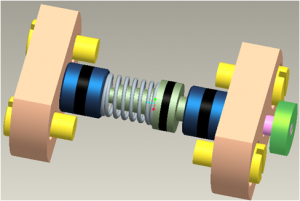

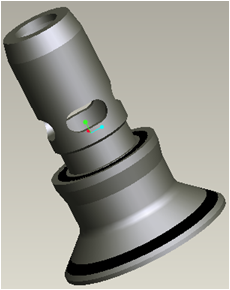

It’s also a highly cost and time effective tool during detailed design when we’re able to integrate data from modeling and analysis into the 3D visual model to present increasingly accurate representations and highlight any areas for additional attention before they become potential problems. In all aspects of our design development work we’re always equipped with the latest modeling and analysis tools.

Reverse Engineering Development

We also provide services in the field of Reverse Engineering Development. Nowadays it’s a very effective and common tool to make a real product or design from the efficient, best performed and existing product.

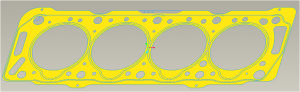

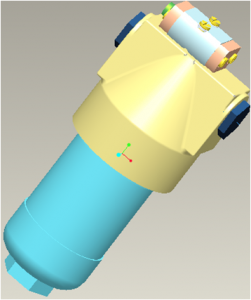

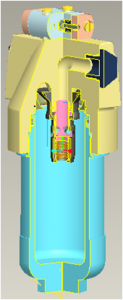

Our R&D Team takes a real product and analyze it to get the all required information and design data from the existing product. Then they make 3D model by using above critical information to verify the design and measure some of the parameters like weight, cost etc. Also they do some simulation analysis to see if there any chance of weight optimization without affecting the performance leading to a cost effective product.

A Few Examples of our Work:

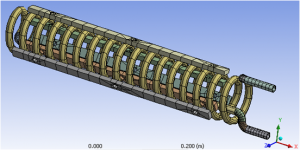

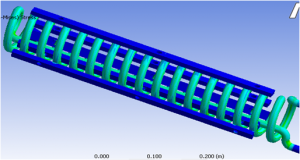

Heating Coil

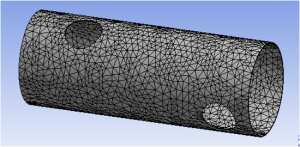

Pressure Vessel

Gasket

Hydraulic Filter

Double Acting Cylinder Valve

Spring Operated Plunger Valve

Mechanical Plunger